Hones and Stones

Hones and stones are essential tools for any automotive mechanic. They are used to sharpen cutting tools, such as chisels, knives, and plane blades. Hones are made of a fine abrasive material, such as diamond or silicon carbide, and are used to create a smooth, polished surface on the tool. Stones are made of a coarser abrasive material, such as emery or Arkansas stone, and are used to remove material from the tool and create a sharp edge.

Types of Hones and Stones

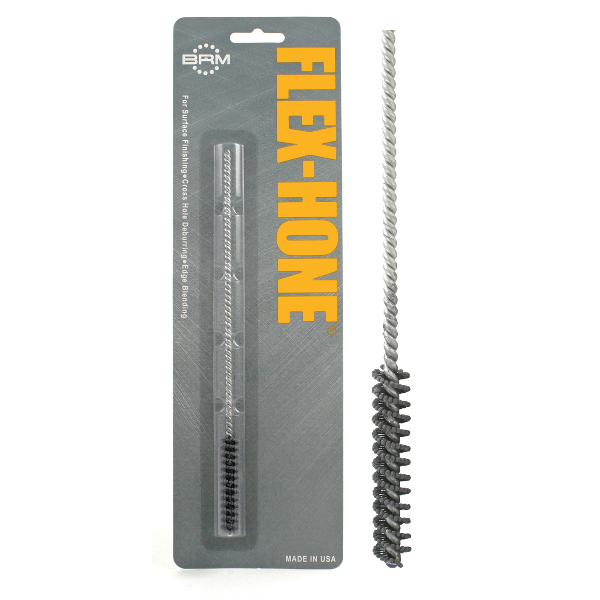

There are two main types of hones: flat hones and cylindrical hones. Flat hones are used to sharpen flat-edged tools, such as chisels and plane blades. Cylindrical hones are used to sharpen round-edged tools, such as knives and drills.

Stones are also available in two main types: water stones and oil stones. Water stones are soaked in water before use, which helps to lubricate the tool and prevent it from overheating. Oil stones are lubricated with oil, which also helps to prevent the tool from overheating.

How to Use Hones and Stones

To use a hone, first wet the hone with water or oil. Then, hold the tool at a 20-degree angle to the hone and move it back and forth in a smooth motion. Continue this process until the tool is sharp.

Tips for Using Hones and Stones

- Use a light touch when sharpening the tool. Applying too much pressure can damage the tool.

- Sharpen the tool regularly to prevent it from becoming dull.

- Store the hones and stones in a dry place when not in use.

Hones and Stones are an essential part of any automotive mechanic's toolkit. They are used to sharpen cutting tools, such as chisels, knives, and plane blades. Hones are made of a fine abrasive material, such as diamond or silicon carbide, and are used to create a smooth, polished surface on the tool. Stones are made of a coarser abrasive material, such as emery or Arkansas stone, and are used to remove material from the tool and create a sharp edge.

Types of Hones and Stones

- Flat hones

- Cylindrical hones

- Water stones

- Oil stones

How to Use Hones and Stones

- Wet the hone with water or oil.

- Hold the tool at a 20-degree angle to the hone and move it back and forth in a smooth motion.

- Continue this process until the tool is sharp.

Tips for Using Hones and Stones

- Use a light touch when sharpening the tool.

- Sharpen the tool regularly to prevent it from becoming dull.

- Store the hones and stones in a dry place when not in use.